Technical data

| Application | Control and on/off application |

|---|---|

| Sizes - standard | R110, R150, R200, R250 |

| Sizes - with reinforced springs | R110v, R150v, R200v, R250v, R250vv |

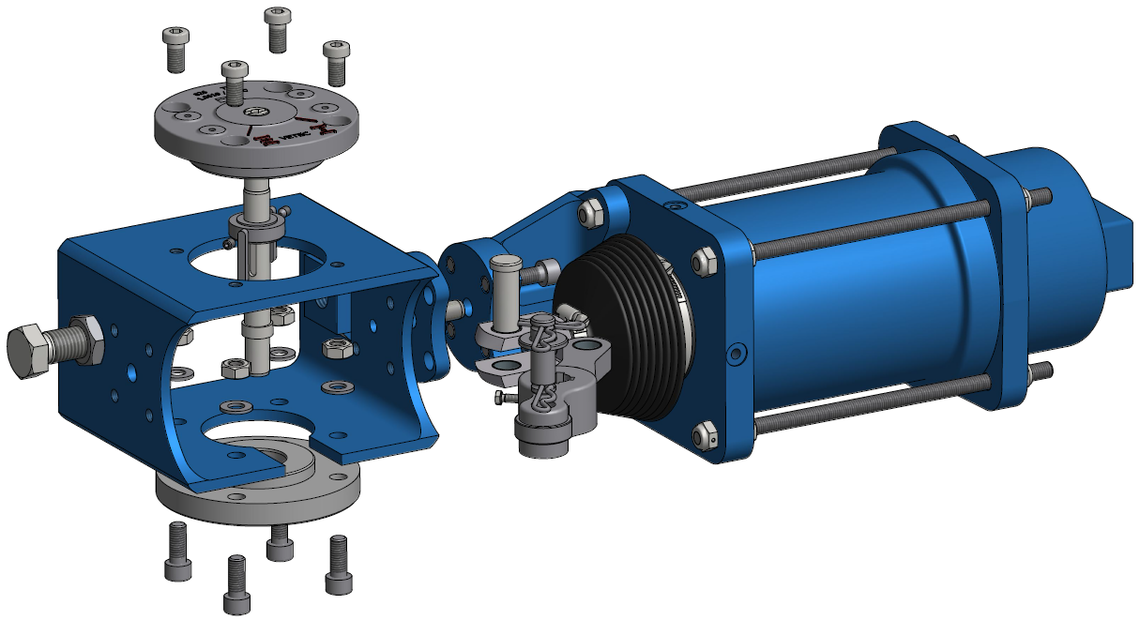

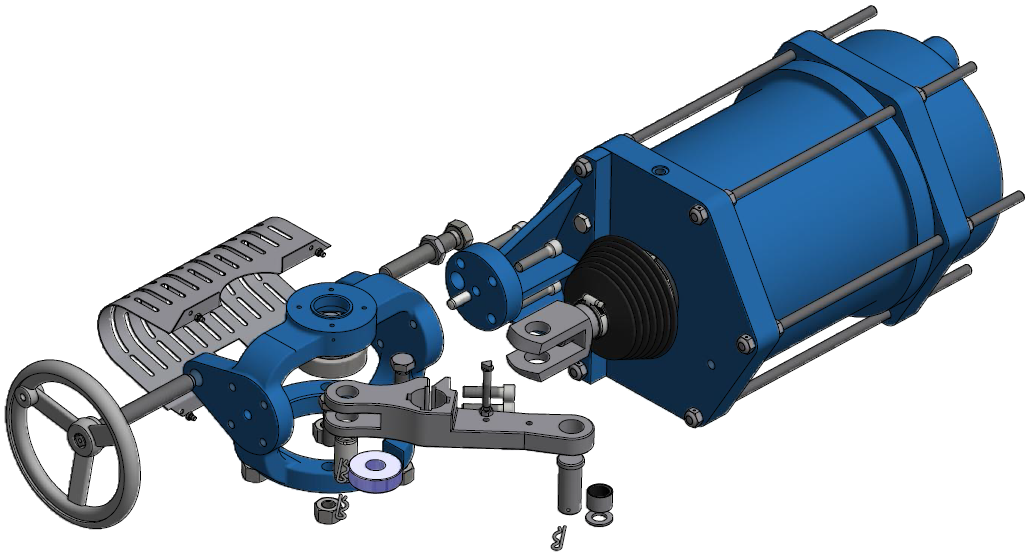

| Design | Rolling diaphragm; single-acting; internal, centrally located spring(s) |

| Actuator movement | rotary |

| Rotary angle | 0 to 75° (optimally matched to VETEC rotary plug valves) |

| Supply air | Pneumatic |

| Control air range | 2 to 6 bar |

| Safety function | Reversible without additional components: Spring force closes (FC) / Spring force opens (FO) |

| Diaphragm area | 87 to 471 cm² |

| Torques | 28 to 1024 Nm |

| Nominal stroke | 128 to 200 |

| Permissible ambient temperature | -40 to +80 °C |

| Differential pressures for actuator sizing | TY005.069 |

| Rotation angle limitation (optional) | Externally adjustable mechanical end stops |

| Interface to valve | According to DIN EN ISO 5211 or VETEC standard |

| Interface for attachments | According to VDI/VDE 3845-1 (EN 15714-3) and VDI/VDE 3847-2 |

| Conformity | EAC |

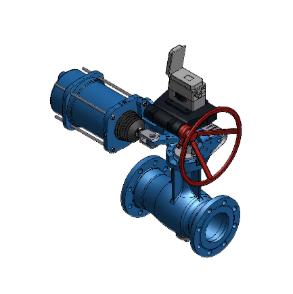

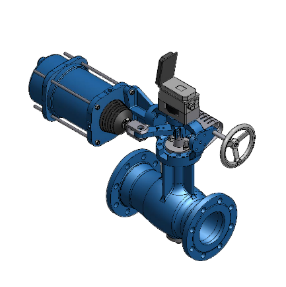

Mounting kits (attachment kits)

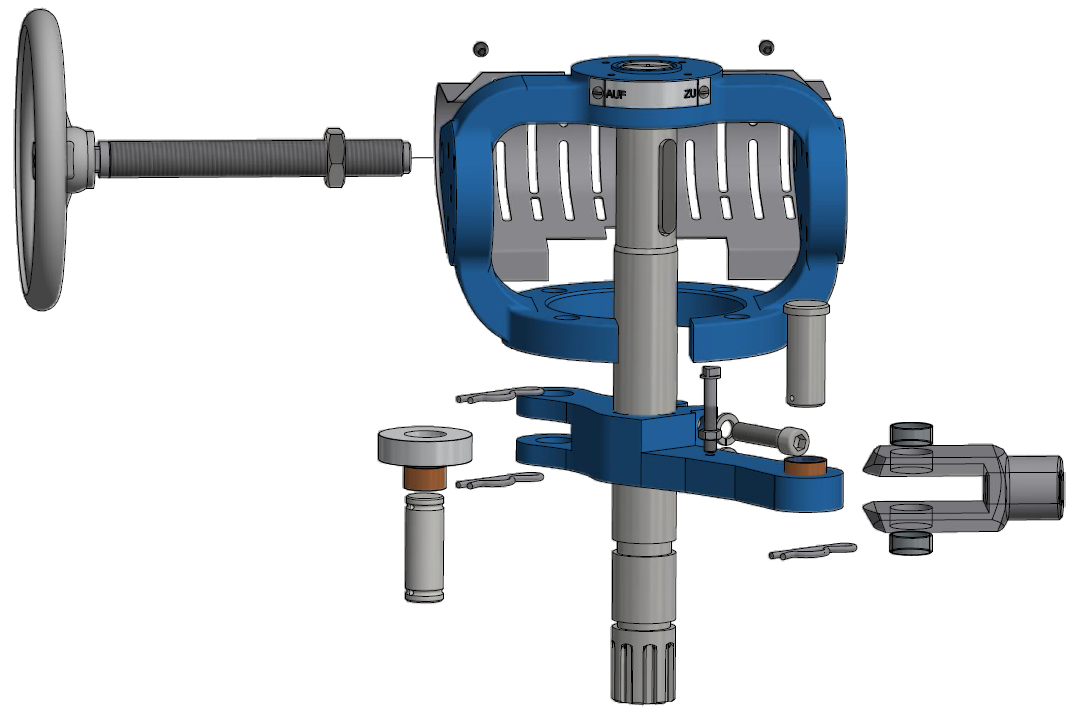

The attachment kit is the link between valve and rotary actuator with an interface according to DIN EN ISO 5211 or VETEC standard and contains the following components:

- Console or bracket → depending on valve series

- Lever kit

- Screws for fastening to the valve

- Screws for mounting the actuator

- Optional mechanical end stops ( rotation angle limitation)

- Position indicator

- Protective cover (cover plate)

Mounting arrangements

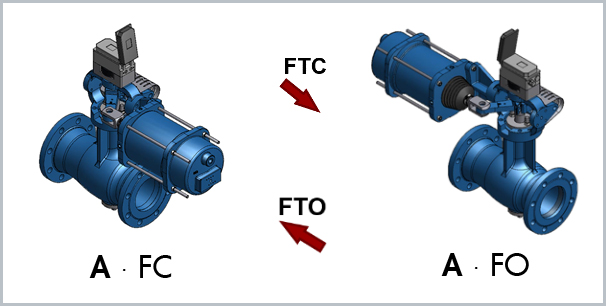

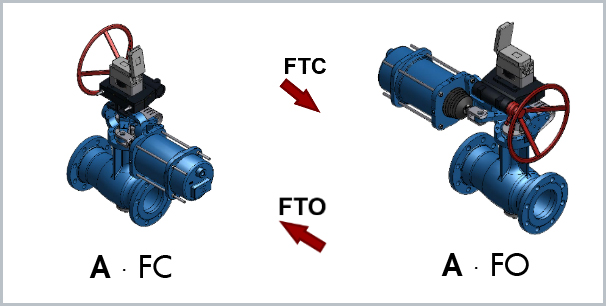

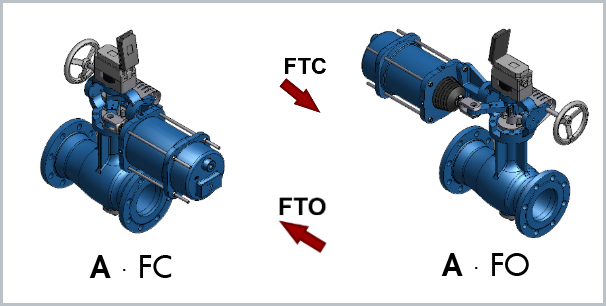

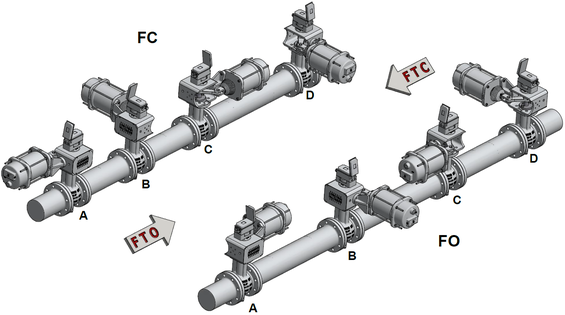

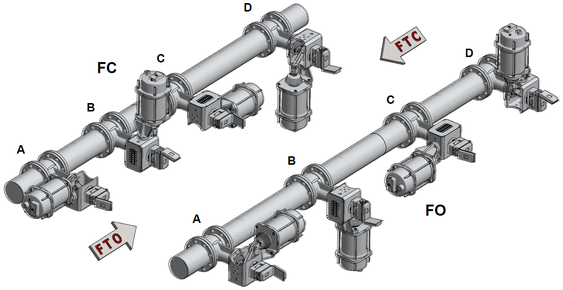

Mounting types A, B, C, D are possible for mounting the actuator to the valve.

Mounting type A is selected as the standard mounting position if no other customer specifications are available.

Exemplary representation of mounting type A. For other mounting types, see data sheet TY005.007.

FC = Spring closes • FO = Spring opens • FTO = Medium opens (flow from the front, from the seat side) • FTC = Medium closes (flow from the rear)

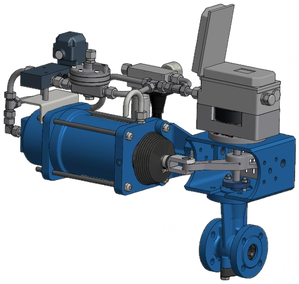

Accessories

The control valves can be equipped with various accessories: Positioner, solenoid valve, supply pressure regulator, limit switch, volume booster/booster and other attachments.

Mounting of accessories (attachments) to pneumatic rotary actuators is performed according to two standardized mounting methods:

EU/CE conformity

| Manufacturer declaration FB002.014 | RL 2014/34/EU (ATEX) | Excluded from the scope according to ignition hazard assessment according to DIN EN 13463-1:2001, para. 5.2 |

| Manufacturer declaration FB002.045 | RL 2014/68/EU (DGRL) | Excluded from the scope of Art. 1, § 2, letter j) |

| Declaration of incorporation FB002.196 | RL 2006/42/EG (MRL) | Incomplete machine (valve actuator with or without interface according to EN ISO 5211) |

Safety integrity level (SIL)

| Manufacturer decleration FB002.012 | IEC 61508/IEC 61511 (SIL) | Applicable up to SIL 2 and with redundant instrumentation up to SIL 3 |

TR CU (EAC)

| Conformity declaration 00125/TPTC/2020 FB002.193 | TP TC 032/2013 (EAC) TP TC 010/2011 (EAC) (TR CU) | Excluded from the scope of TP TC 032/2013 (Safety of pressure equipment - PED) and TP TC 010/2011 (Safety of machinery - MRL). (RU, BLR, KAZ) |

| Certificate RU C-DE.ГБ08.B.02294 FB002.152 | TP TC 012/2011 (EAC/Ex) (TR CU) | Safety of equipment for use in potentially explosive atmospheres (RU, BLR, KAZ) (ATEX) |