Technical Data

|

DIN EN 558 Table 2 R 1, 15 |

| DN 25 to 600 |

| PN 10, 16, 25, 40 |

|

DIN EN 1092-1 |

| Metal seal · Soft seal |

| F1 (100 %) · F0,6 (60 %) · F0,4 (40 %) · F0,25 (25 %) |

| Flow to close (FTC) · Flow to open (FTO) |

| Equal percentage or linear using a positioner · inherent |

| Up to 200:1 |

|

–196 to +500 °C |

|

Metal seal: IV acc. to DIN EN 60534-4 and ANSI/FCI 70-2 Soft seal: VI acc. to DIN EN 60534-4 and ANSI/FCI 70-2 |

|

DIN EN 558 Table 2 R15, 37, 38 ISA 75.08.01 up to DN 250 |

| NPS 1 to 24 |

| CL 150, 300 |

|

ANSI/ASME B16.5 |

| Metal seal · Soft seal |

| F1 (100 %) · F0,6 (60 %) · F0,4 (40 %) · F0,25 (25 %) |

| Flow to close (FTC) · Flow to open (FTO) |

| Equal percentage or linear using a positioner · inherent |

| Up to 200:1 |

|

–321 to +932 °F |

|

Metal seal: IV acc. to DIN EN 60534-4 and ANSI/FCI 70-2 Soft seal: VI acc. to DIN EN 60534-4 and ANSI/FCI 70-2 |

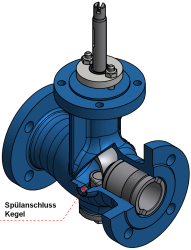

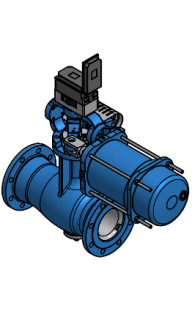

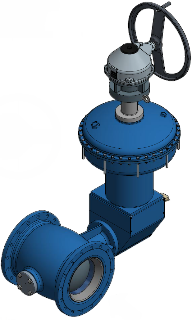

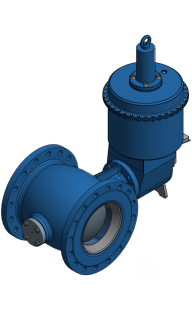

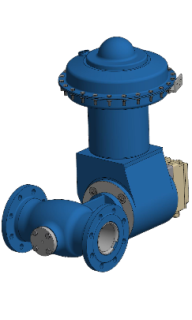

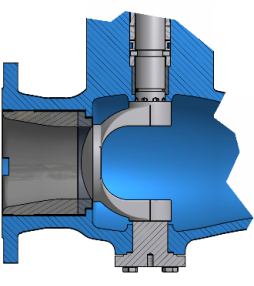

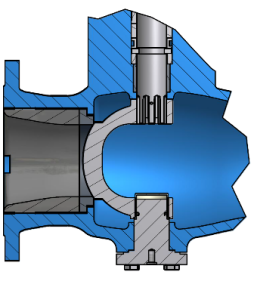

Sample Configurations

The rotary plug valve can be configured with pneumatic, electric or hydraulic actuators and can be equipped with various accessories.

![[Translate to English:] Typ 72.3-IT2](/fileadmin/Subsidiaries/VETEC/products/72.3/72.3-IT2.png)

![[Translate to English:] Typ 72.3-IT1](/fileadmin/Subsidiaries/VETEC/products/72.3/72.3-IT1.png)

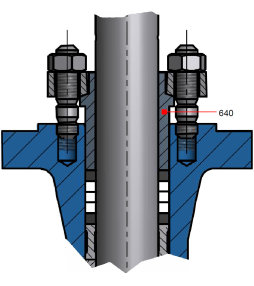

![[Translate to English:] Typ 72.3-DSB](/fileadmin/Subsidiaries/VETEC/products/72.3/72.3-DSB.png)

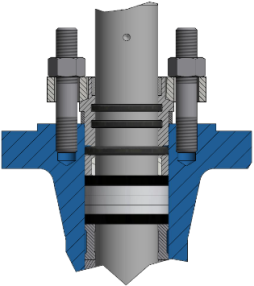

![[Translate to English:] Typ 72.3-Heizmantel](/fileadmin/Subsidiaries/VETEC/products/72.3/72.3-Heizmantel.png)